Our solution

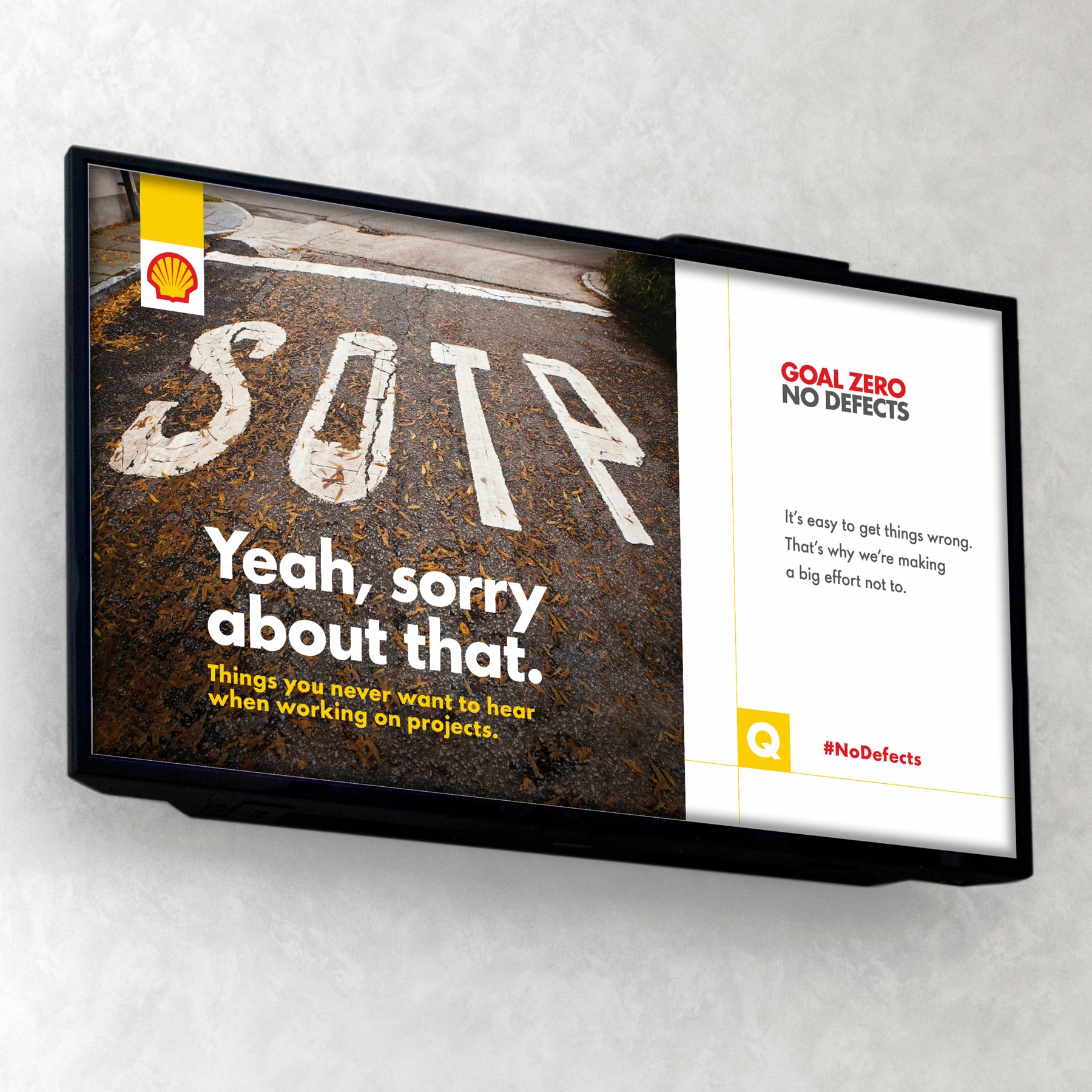

We decided it was crucial to define No Defects in a simple, memorable and actionable way.

We developed three core principles by gathering together a cross-section of people from the quality and projects communities in a discovery meeting. The stakeholders were involved and consulted throughout the process.

We then created four workshops – an introduction to No Defects and a session on each of the three principles. We deliberately built in flexibility so teams could do the sessions at a time and a pace that was best for them, as some areas needed to do some preparation and complete other priorities first.

We trained a global team of No Defects Champions to deliver the workshops at their regional projects and gave them a toolkit of resources. After the sessions, the attendees can deepen their understanding by visiting a SharePoint site full of resources.

We also proposed a global clock which shows how many consecutive days of No Defects there have been.